What makes

us special

Quality at its Best

Certified by FSSAI, FSSC 22000, and Halal, we promise chemical-free, antibiotic residue-free chicken for our cherished customers. You deserve the absolute best, and that’s what we deliver!

Processing Perfection

Our plants are a marvel! With digital incubators, automated sorting machines, HACCP-compliant conveyor belts, and stringent vaccination protocols, we craft top-tier chicken products that exceed your expectations!

Unmatched Food Service

We are the go-to partner for quick-service restaurants and caterers, providing tailor-made products backed by our stellar R&D team. Your satisfaction is our priority!

Innovating for You

Innovation is our heartbeat! Our passionate team relentlessly brings fresh, innovative products to your table. Market research drives us to deliver nothing but the BEST to our beloved customers!

Antibiotic Residue Free

Your health matters! We go the extra mile to ensure our chicken products are antibiotic-free, ensuring health, freshness, and trust in every bite.

Power-Packed Protein

Monitored rigorously and processed in-house, our chicken products are packed with protein and bursting with flavor. Nutritious and delicious – just the way you like it!

vertical integration

Skylark Foods, a subsidiary of the Skylark Group, operates as part of one of India’s largest vertically integrated poultry businesses. In 2002, Skylark Foods was established to meet the market demand for delicious and nutritious chicken products. The company is committed to producing premium, high-quality antibiotic-free chicken products at its poultry processing plant in Rai Sonipat, Haryana, ensuring a year-round supply directly to consumers' dinner tables.

Skylark Group is a vertically integrated poultry producer that rear three generations of birds from grandparent stock and parent stock to commercial broiler stock. This gives us 100% traceability of bird genealogy and life cycle history, ensuring complete quality control.

To provide disease-free chicken to our customers, we implement rigorous biosecurity measures across all farms, ensuring strict hygiene, timely vaccinations, and sanitization of water feeders.

Our comprehensive approach prevents any disease transmission from grandparent to parent and from parent to commercial broiler livestock & also helps to provide 100% traceability of bird genealogy and life cycle history.

The chemical-free and toxin-free nature of a chicken product depends on the quality of feed the bird consumes during its life.

By using our in-house Skylark Feed, exclusively made from nutritious, balanced ingredients such as soybean, corn, and essential minerals, we eliminate reliance on external suppliers and the associated risk of adulteration; paired with highly sophisticated labs equipped with one of a kind machines that help us produce 100% chemical and toxin free feed.

Stringent quality management standards are upheld throughout our food processing journey, starting with livestock transport to our processing plants. Trucks undergo sanitization fogging for biosecurity measures upon livestock arrival. All the birds are physically tested by skilled veterinarians. The plant employs cutting-edge technology and a modern facility, adhering to FSSAI’s comprehensive food safety protocols.

Processing occurs at a controlled 10-12°C temperature to maintain hygiene standards. Our staff strictly adhere to security guidelines, and undergo regular medical checks, ensuring quality food. Finished products are stored in cold storage units.

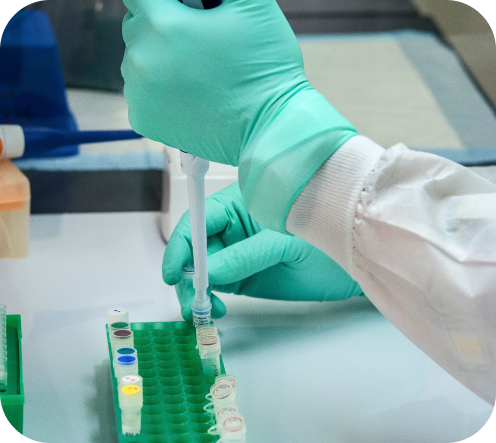

Skylark Foods has a fully-equipped in-house microbiological lab installed in the production facility. Sample from each production batch is taken and tested in the lab according to preparation information provided on the packaging by assessing structure, colour and taste.

But it doesn’t end there! Our expert meat technologists continuously push boundaries, testing and developing new products in small batches to ensure each creation meets the pinnacle of excellence.

Quality is what makes us SKYLARK FOODS.